vickers hardness test measures force in what unit|vickers hardness test theory : factories As with every other hardness test, the Vickers procedure uses its own unit of hardness. This is called as the Vickers Pyramid Number (HV) or the Diamond Pyramid Hardness (DPH). These units are convertible to pascals .

Resultado da A dose inicial é de 1 cápsula de 8,37 mg por dia. A dose pode ser aumentada para 1 cápsula de 12,556 mg, por dia, mas só depois de o seu médico .

{plog:ftitle_list}

Como negociar minha dívida com a Oi? No Oi Negocia é possível verificar quais são os débitos e quitar os valores de modo bastante simples. Para isso, confira abaixo como .

The Vickers method is based on an optical measurement system. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation which is measured and .The Vickers Hardness number (HV) is the ratio of the load applied to the surface area of the indention. This is done with the following calculator and formula. HV = P / ( 0.5393 d 2 ) or. HV = 0.1891 F / d 2. Where: P = Force (kg) d = Area of .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of h.Find an explanation of how to read a Vickers hardness value (e.g. “640 HV30”), and of the meaning of the numbers and letters.

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers . As with every other hardness test, the Vickers procedure uses its own unit of hardness. This is called as the Vickers Pyramid Number (HV) or the Diamond Pyramid Hardness (DPH). These units are convertible to pascals .Most Vickers hardness testing machines use forces of 1, 2, 5, 10, 30, 50 and 100 kgf and tables for calculating HV. SI would involve reporting force in newtons (compare 700 HV/30 to HV/294 .To calculate Vickers hardness number using SI units we must convert the force applied from kilogram-force to Newtons by multiplying by 9.80665 (standard gravity) and then dividing by 1000 to get the answer in GPa.

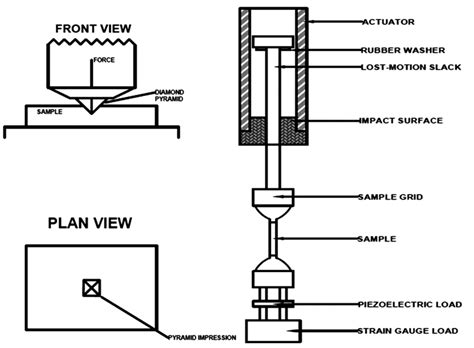

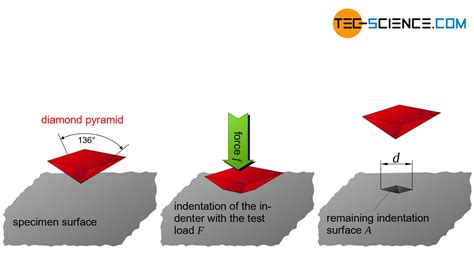

The Vickers hardness test uses a square-based pyramid diamond indenter with an angle of 136° between the opposite faces at the vertex, which is pressed into the surface of the test piece using a prescribed force, F. Vickers Hardness, HV = Applied test force in kilogram-force (kgf) ÷ Surface area of indentation (mm 2) or, HK = 1.854 x (F/D 2) By making use of a diamond-shaped indenter as opposed to a sphere (such as in the Brinell .The force term (F) in the numerator has a unit of kgf and the diameter term (D) has a unit of mm. . The Brinell hardness test measures the diameter of the indentation to calculate the hardness value. . Table 2: Brinell, Rockwell & .In the Vickers hardness tests, both diagonals of the indent are measured and the average value is used to compute the Vickers hardness number (HV) (Fig. 4 A). In the Knoop hardness tests, only the longer diagonal is measured and the Knoop hardness is calculated based on the projected area of the indent divided by the applied force.

A Vickers hardness tester. There are three main types of hardness measurements: scratch, indentation, and rebound. . Scratch hardness is the measure of how resistant a sample is to fracture or permanent plastic deformation due to friction from a sharp object. [1] . showing the relationship between stress (force applied per unit area) and .Where F is in kgf and d is in millimeters. The corresponding units of HV are then kilograms-force per square millimeter (kgf/mm). To calculate Vickers hardness number using SI units we must convert the force applied from kilogram-force to Newtons by multiplying by 9.80665 (standard gravity) and then dividing by 1000 to get the answer in GPa.

Ask the Chatbot a Question Ask the Chatbot a Question Vickers hardness, a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. Devised in the 1920s by engineers at Vickers, Ltd., in the United Kingdom, the diamond pyramid hardness test, as it also became known, permitted the . Figure: Vickers hardness test procedure. In the Vickers hardness test, a four-sided diamond pyramid is pressed into the material to be tested. The indentation surface left behind serves as a measure of the hardness value! The factor 0.102 again comes from the no longer used unit “kilopond” (see Brinell hardness test). The indentation .The unit of hardness can be measured as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). . The Vickers hardness test was developed by George E. Sandland and Robert L. Smith at Vickers Ltd. in the year 1921, as an alternative to the Brinell method to determine the hardness of materials. . (indicating a dwell time of 30 .According to ISO 6507: The dwell time of the test load, but only if this is not between 10 and 15 seconds (uncommon in practice) Examples. 640 HV30. 640 .hardness value; HV .as per Vickers; 30 .with test load of 30 kgf (or test force of 294.2 N ) 610 HV10/30. 610 .hardness value; HV .as per Vickers; 10 .with test load of 10 kgf (or .

The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but should not be confused with pressure, which also has units of pascals. The hardness number is determined by the load over the surface area of the indentation .Vickers hardness measurement is a technique used to measure the hardness of a material and compare it to other materials by using a Vickers hardness number. From: Durability of Composite Systems, 2020. . If the Vickers test is performed with low indenting forces (≤10 N) then that is microhardness. .Most Vickers hardness testing machines use forces of 1, 2, 5, 10, 30, 50 and 100 kgf and tables for calculating HV. SI would involve reporting force in newtons (compare 700 HV/30 to HV/294 N = 6.87 GPa) which is practically meaningless and messy to engineers and technicians.

An easy-to-use vacuum impregnation unit, specially designed to make the impregnation of porous materials simple. . However, historically, loads were expressed in kilogram-force (kgf), gram-force (gf), or pond (p). The correlation between kgf, kp, and N is: 1.0 kgf = 1,000 gf = 1.0 kp = 9.81 N. . For the Vickers hardness test, the measured . The Vicker hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The two diagonals of the indentation left in the surface of the material after .Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is .

• rebound hardness The Vickers Hardness test measures the indentation hardness for small parts or thin sections of metals, ceramics, and composites – almost any . and also the Rockwell method which used multiple test forces; the Vickers Hardness test is easy to use and offers a number of advantages over other hardness tests, such as .Learn more about hardness testing basics here. The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an . The Leeb hardness value can be converted into other hardness units, such as Rockwell and Brinell hardness. 5. Shore Hardness (HSD) Shore hardness measures the hardness of non-metallic materials by evaluating the material’s resistance to a specific indenter shape. Shore hardness values can be converted into other hardness units. Note: The commonly used units for hardness measurement are: Brinell Hardness Number (HB) Vickers hardness number (HV) . ball is held in place for a predetermined time, usually for around 30 seconds, and a force is applied to the ball. This force will vary depending on the test metal being measured. . The third way for measuring material hardness .

testing zinc coating thickness

The basic principle, as with all common measures of hardness, is to observe the questioned materials' ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV . The 140HV value represents the hardness value, whilst HV represents the measure being used, Hardness Vickers. The final number following HV represents the amount of force applied to the test load. The load is measured in KGF (kilograms of force), 30KGF. Vickers testers are suitable for testing a variety of materials.5. Wide Hardness Range. The Vickers hardness test can measure a wide range of hardness values, from very soft materials to extremely hard ones. This makes it suitable for testing materials with a wide range of mechanical properties, including those used in aerospace, automotive, and construction industries. 6. Microhardness Testing

Vickers Hardness Test: Utilizing a square-based pyramidal diamond indenter, this test calculates hardness based on the indentation’s surface area. It’s applicable to a wide range of materials and provides precise results. . this test measures the material’s resistance to indentation using a standardized indenter. It’s crucial for .The Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an indenter when it is pressed with a fixed load. You can also use it to measure the indentation hardness of non-metallic materials, provided they are sufficiently dense.

When the unit of test force F is kgf: . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . Nano hardness measurement involves measuring the indentation depth and then calculating the contact area using an empirical formula, whereas traditional hardness measurement .The specimen size (the minimum clearances between test points (indent spacing) and from the specimen edge (edge clearance) for Vickers defined in the standard must be observed); The specimen thickness (the specimen thickness must be at least 1.5 times the indentation diagonals, i.e. the minimum specimen thickness must be between 0.085 and 6.5 mm); The surface .The 3842 Vickers Hardness Tester is engineered to produce a clear indentation and a more precise measurement. By means of a load cell, closed circuit system for control, the CPU controls testing force to . Dwell time of the test force: 0~60s (5 second as a unit) Max. height of the specimen: 170mm Max Depth of . The Vickers hardness test .

vickers hardness testing machine diagram

vickers hardness test theory

vickers hardness test pdf

Resultado da July 20, 2022. 1h. 13+. Young actress and dancer Daniella Perez disappears after filming scenes of a soap opera written by her mother, Gloria Perez. .

vickers hardness test measures force in what unit|vickers hardness test theory